1C:ERP Manufacturing Subsystem

Explore the "Manufacturing" subsystem in 1C:ERP, a complete solution for manufacturing enterprises, supporting over 1,000 end-to-end processes.

Why Use the "Manufacturing" Subsystem?

The key benefits of manufacturing management processes in 1C:ERP are:

Providing high-quality customer service

- Ensuring feasible production timelines based on customer requests

- Timely fulfillment of obligations to customers regarding deadlines and product range

- Monitoring the progress of order fulfillment

Flexible operational management system

- Managing priorities for order fulfillment

- Creating a production schedule aligned with available capacities and resources

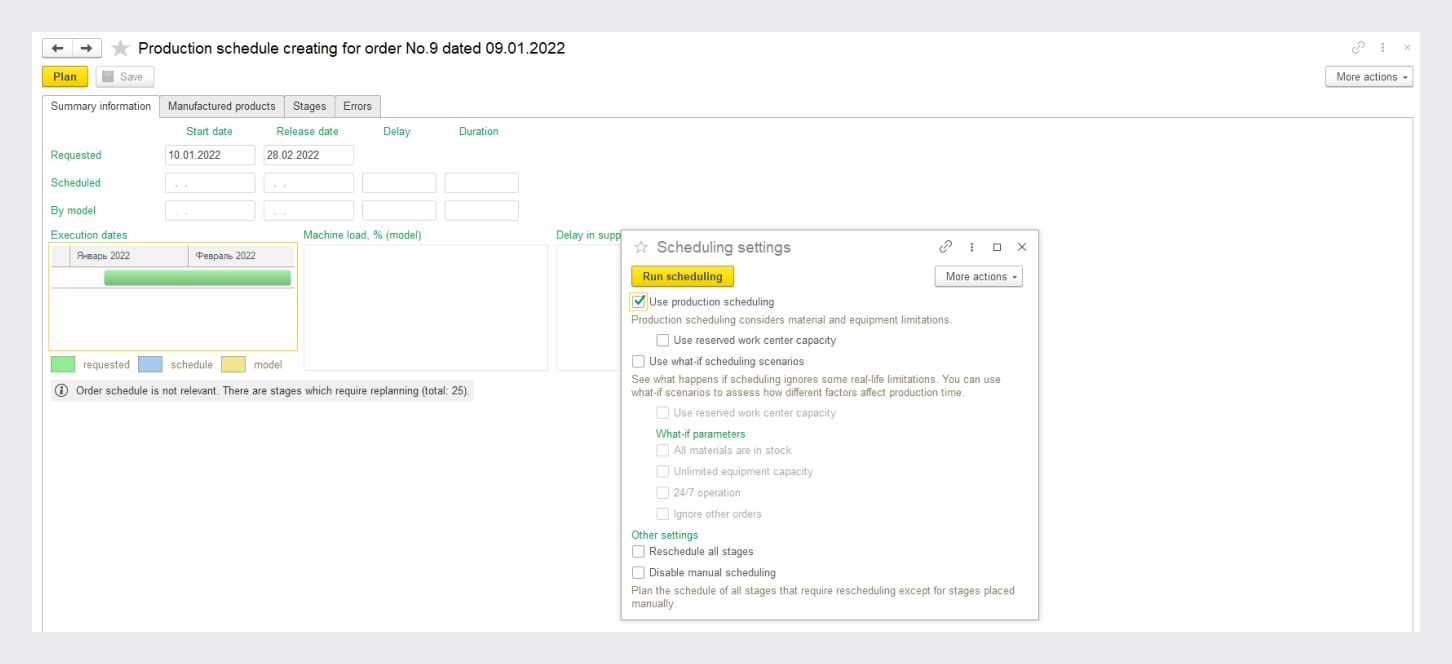

- Prompt response to deviations in schedule and changes in orders, including rescheduling

Efficient use of production resources and cost reduction

- Excluding activities not driven by external or internal demand

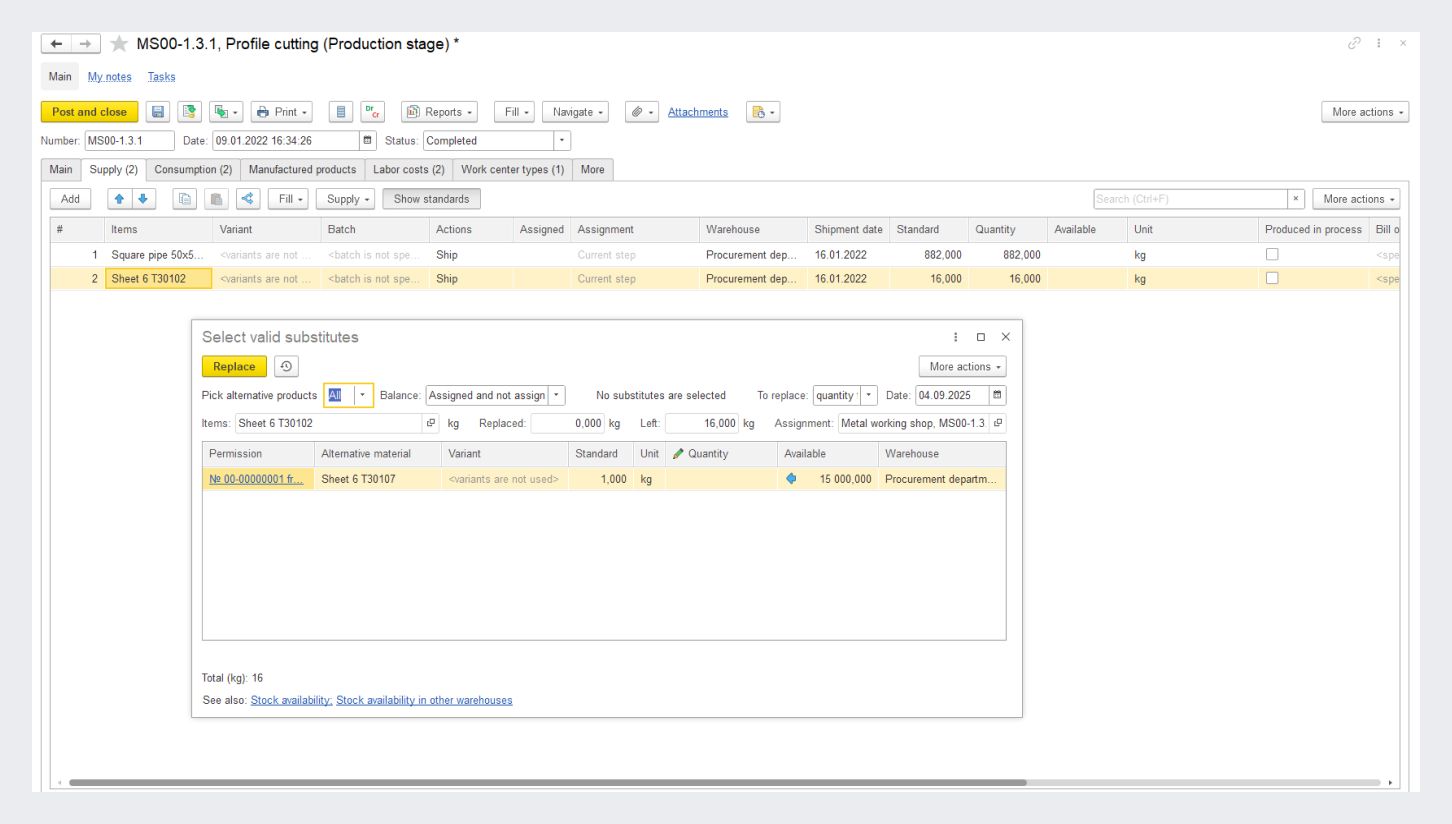

- Controlling compliance with standards and the use of substitutes or alternative products

- Staff motivation

Levels of Production Planning in 1C:ERP

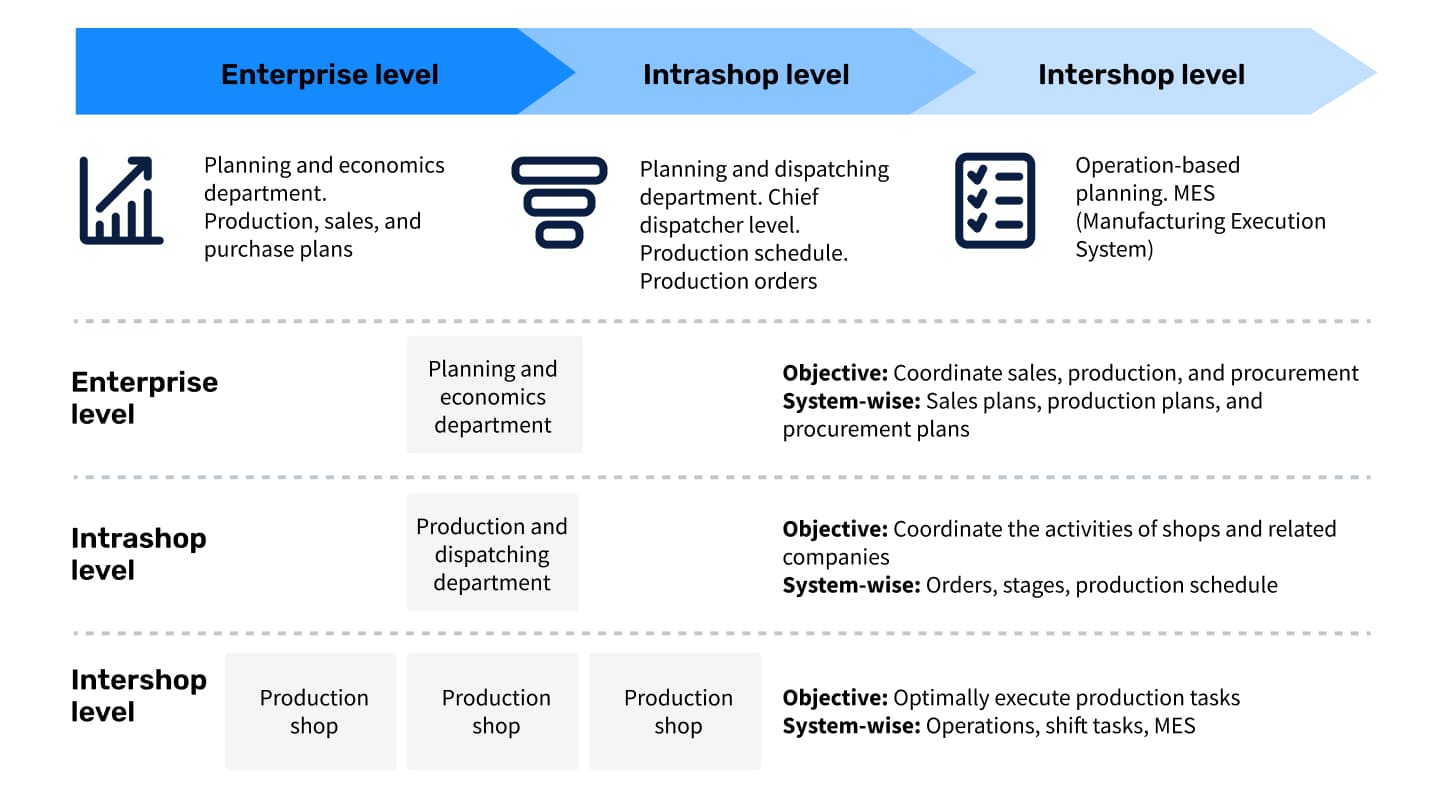

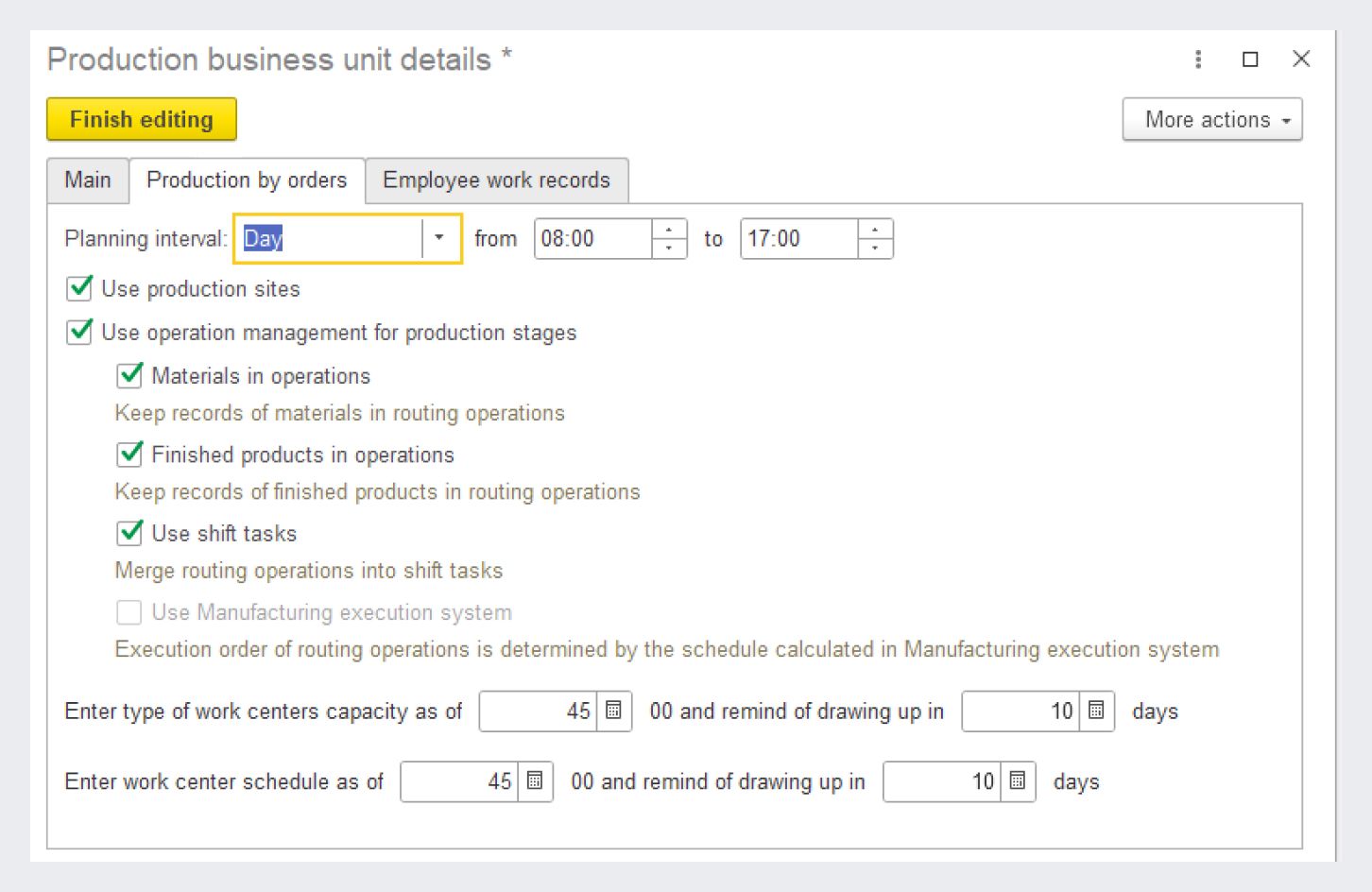

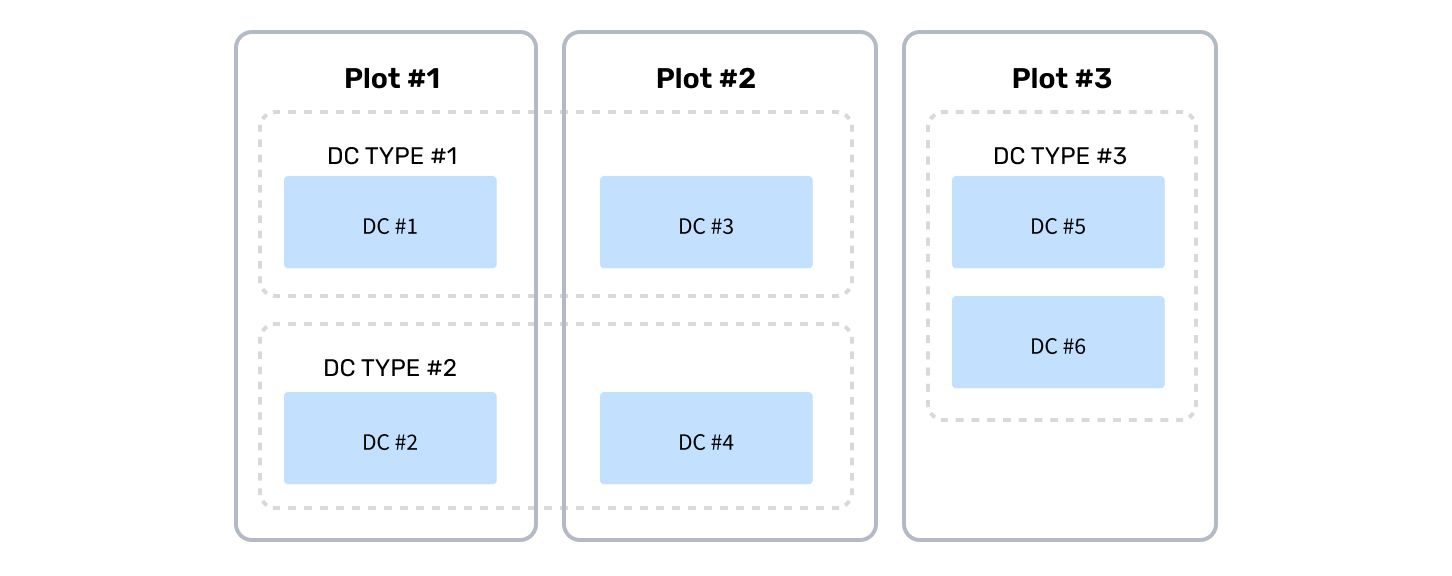

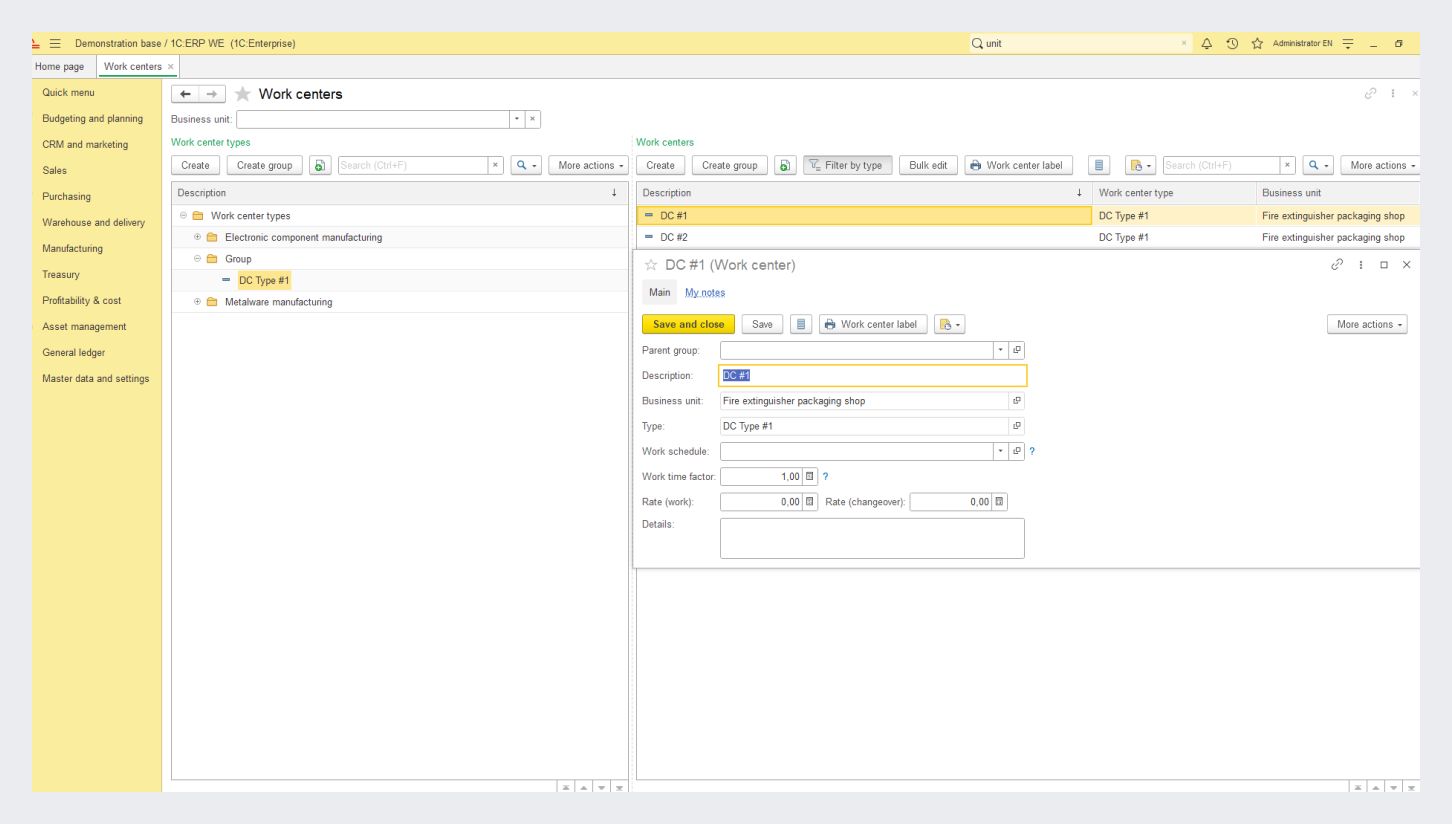

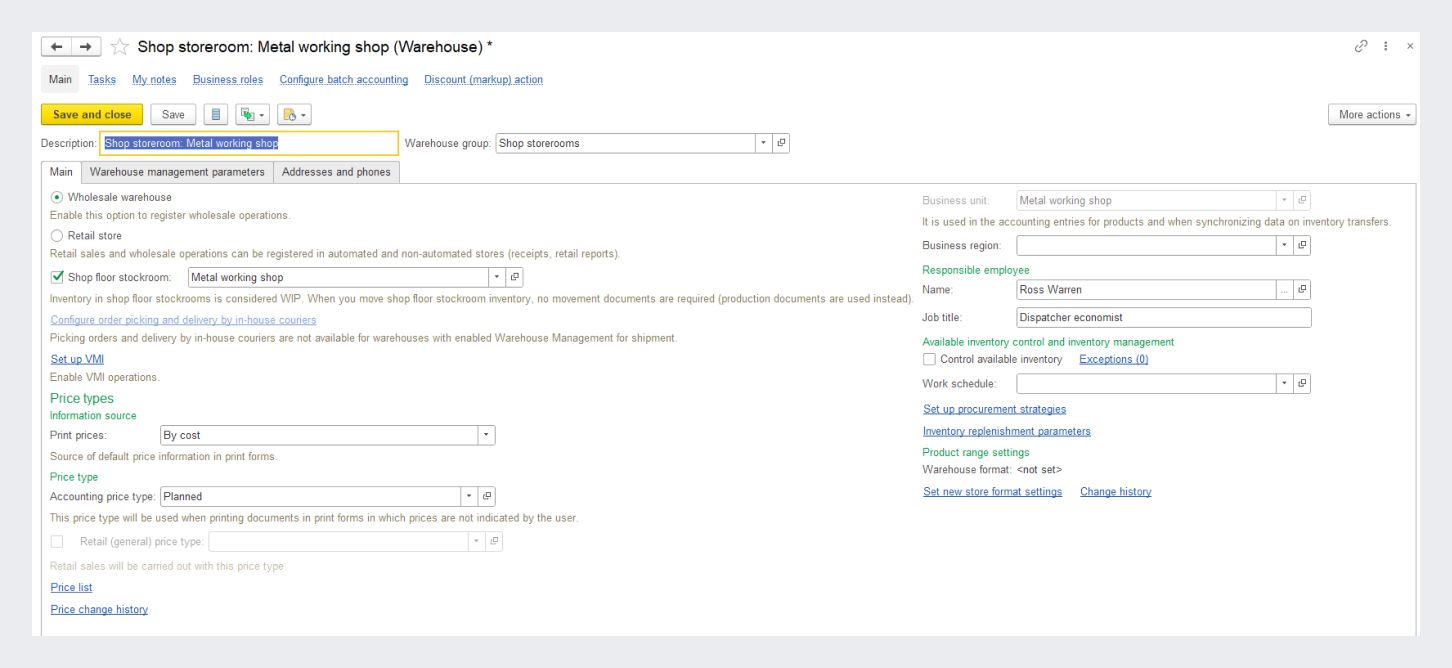

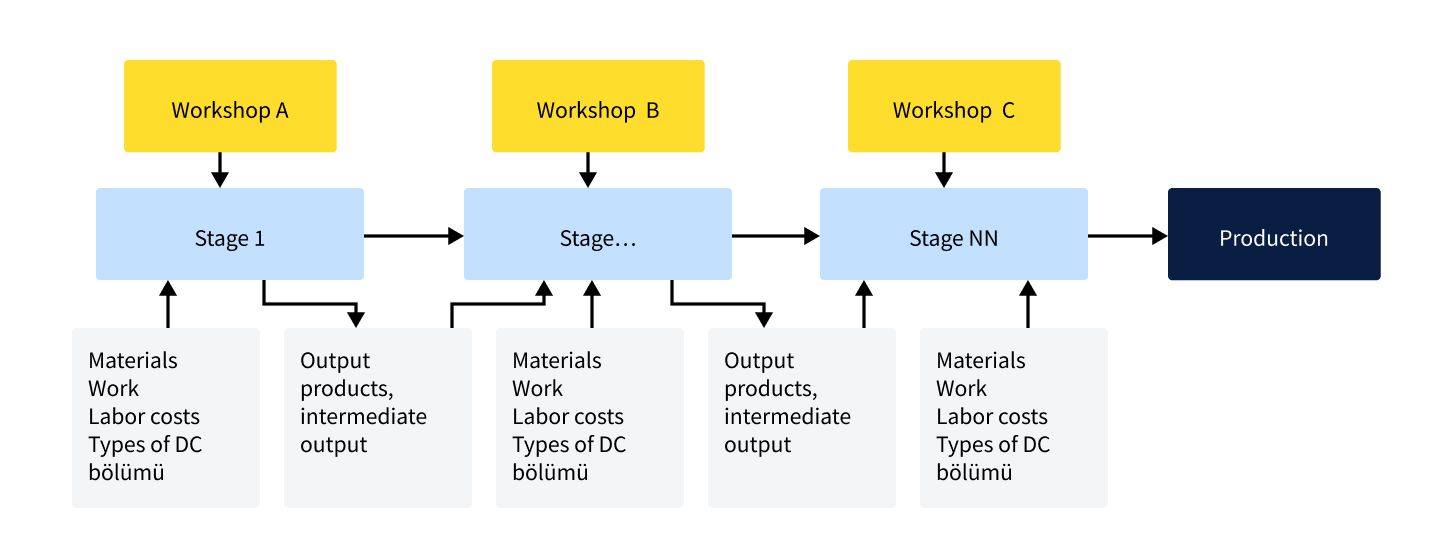

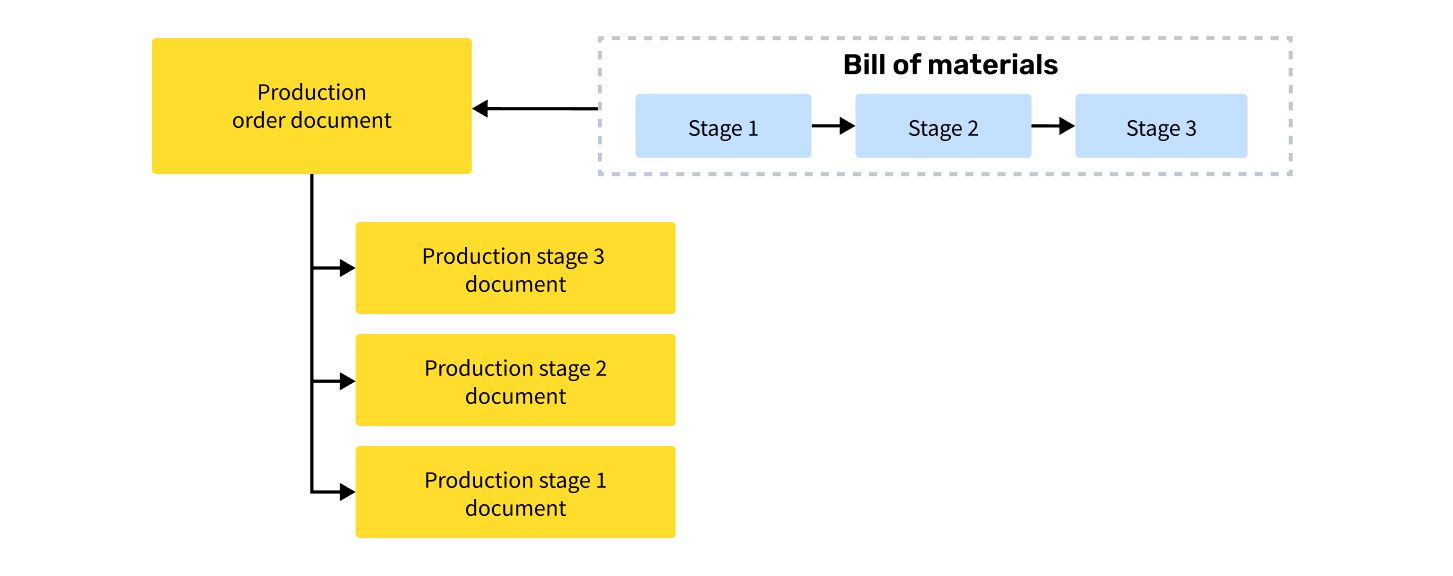

The system enables simple accounting of production processes as well as production planning and management at various levels. Production planning in 1C:ERP can be roughly divided into three levels: enterprise level, intershop level, and intrashop level.

Enterprise-level planning in 1C:ERP involves the creation of a coordinated set of plans: production plans, procurement plans, and sales plans. The primary objective of this planning level is to synchronize the activities of various business units.

In order to develop well-balanced plans in 1C:ERP, the "Budgeting and Planning" subsystem can be used. The "Manufacturing" subsystem is used to manage activities at the intershop and intrashop level.

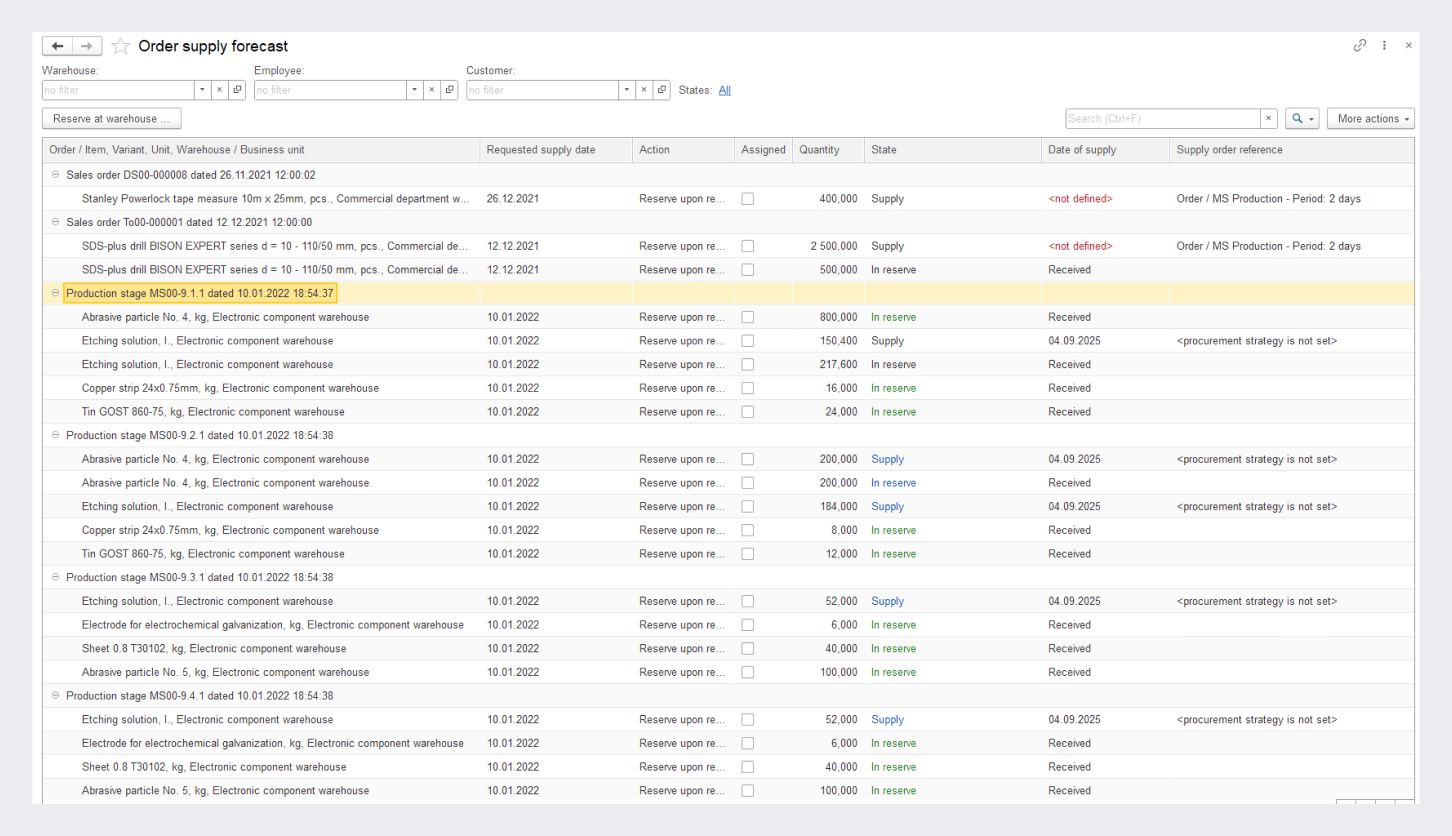

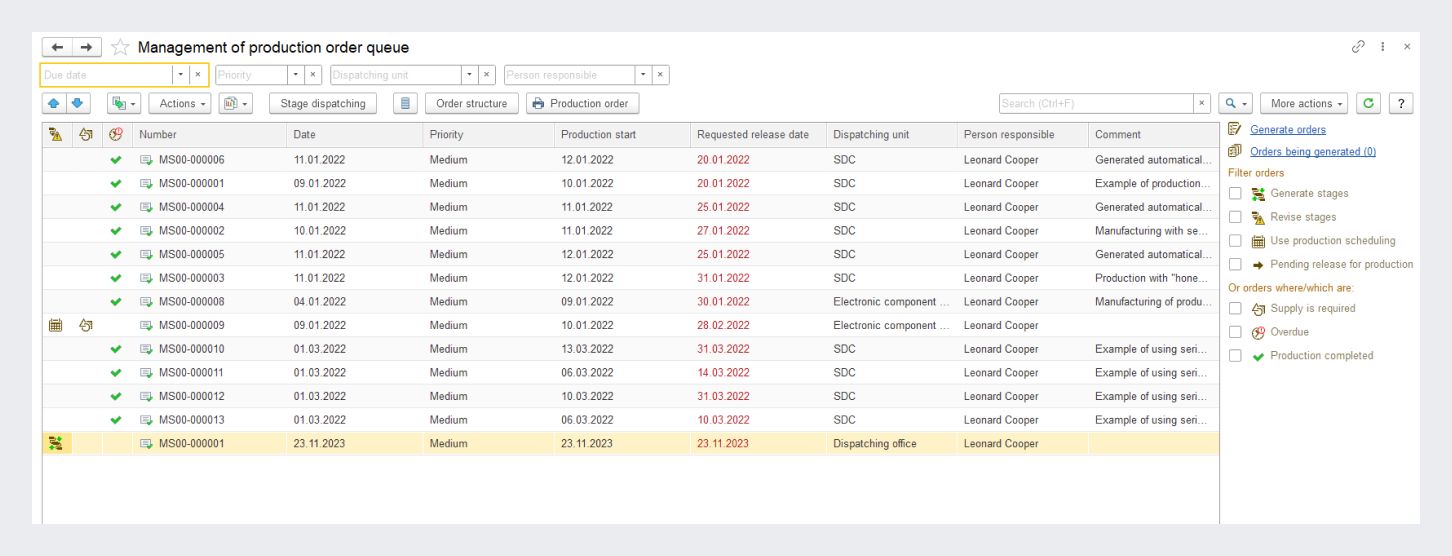

The operations management system streamlines the planning and dispatching of production processes. It facilitates to determine the sequence of products launched into production, to create the necessary material and production reserves, and to ensure a continuous supply of materials and semi-finished products to workplaces. These tasks are addressed based on the type of production, as well as the organizational and technological specifics of production processes.

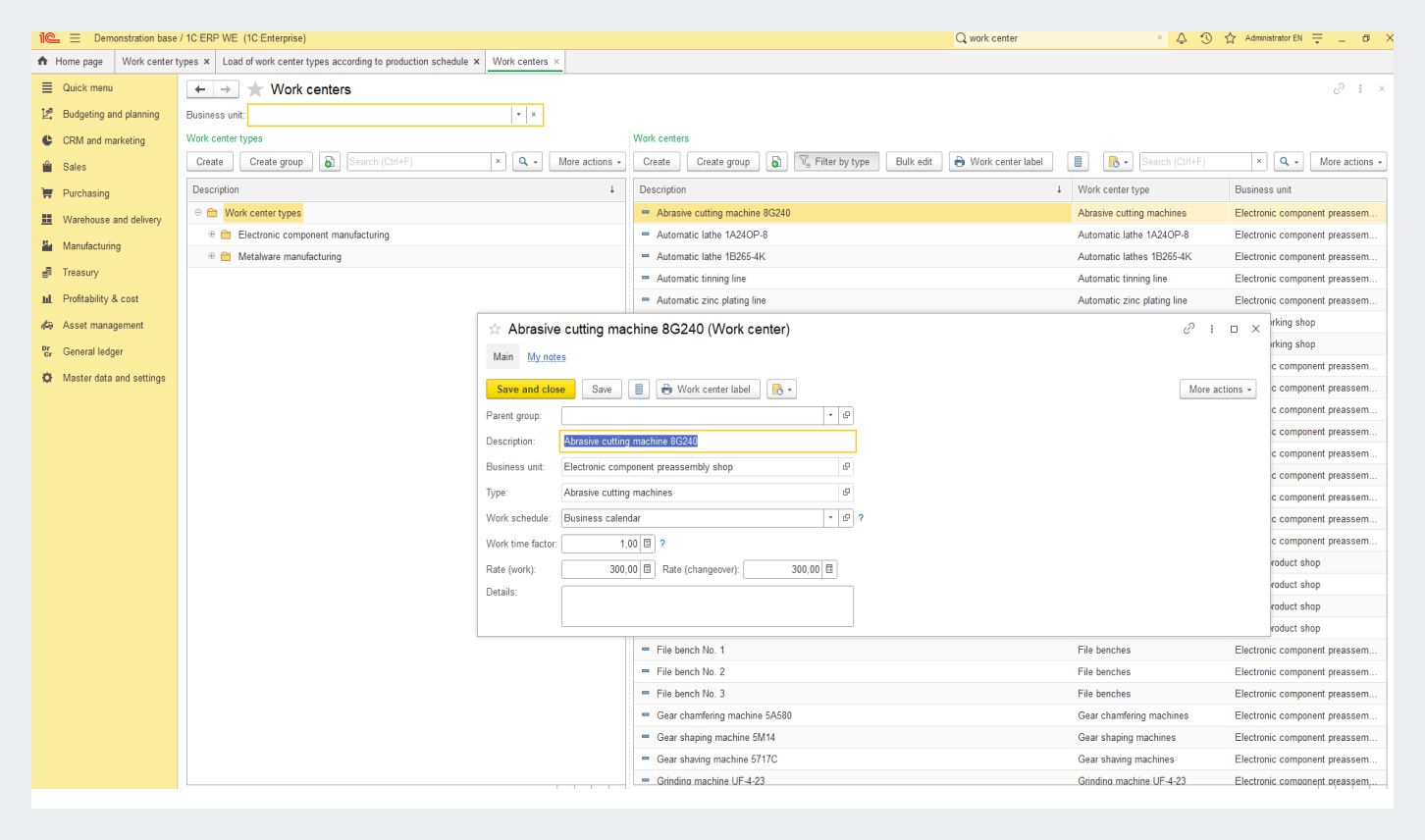

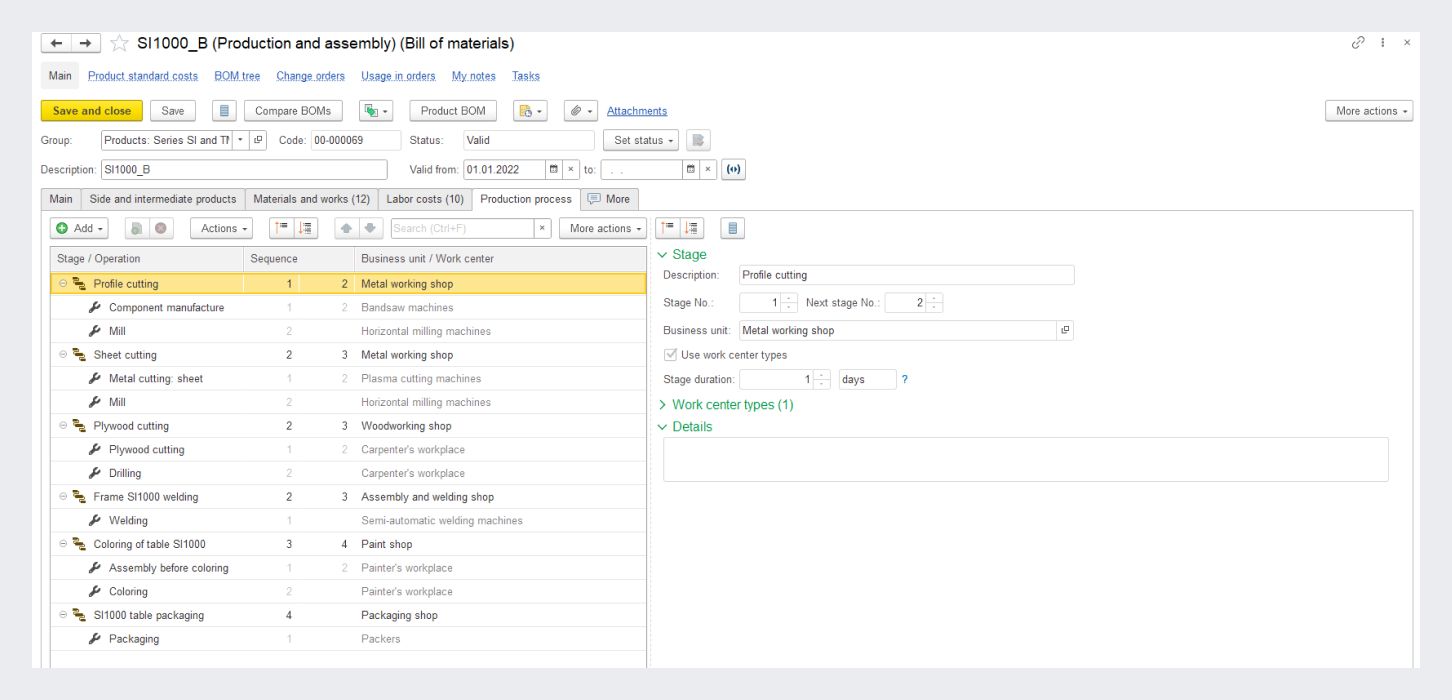

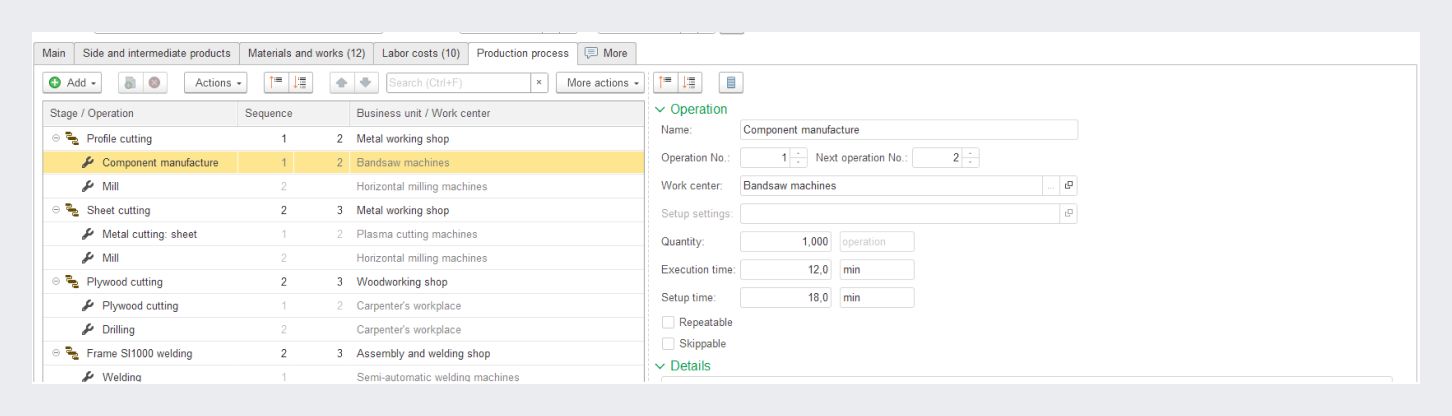

Master Data for the “Manufacturing” Subsystem

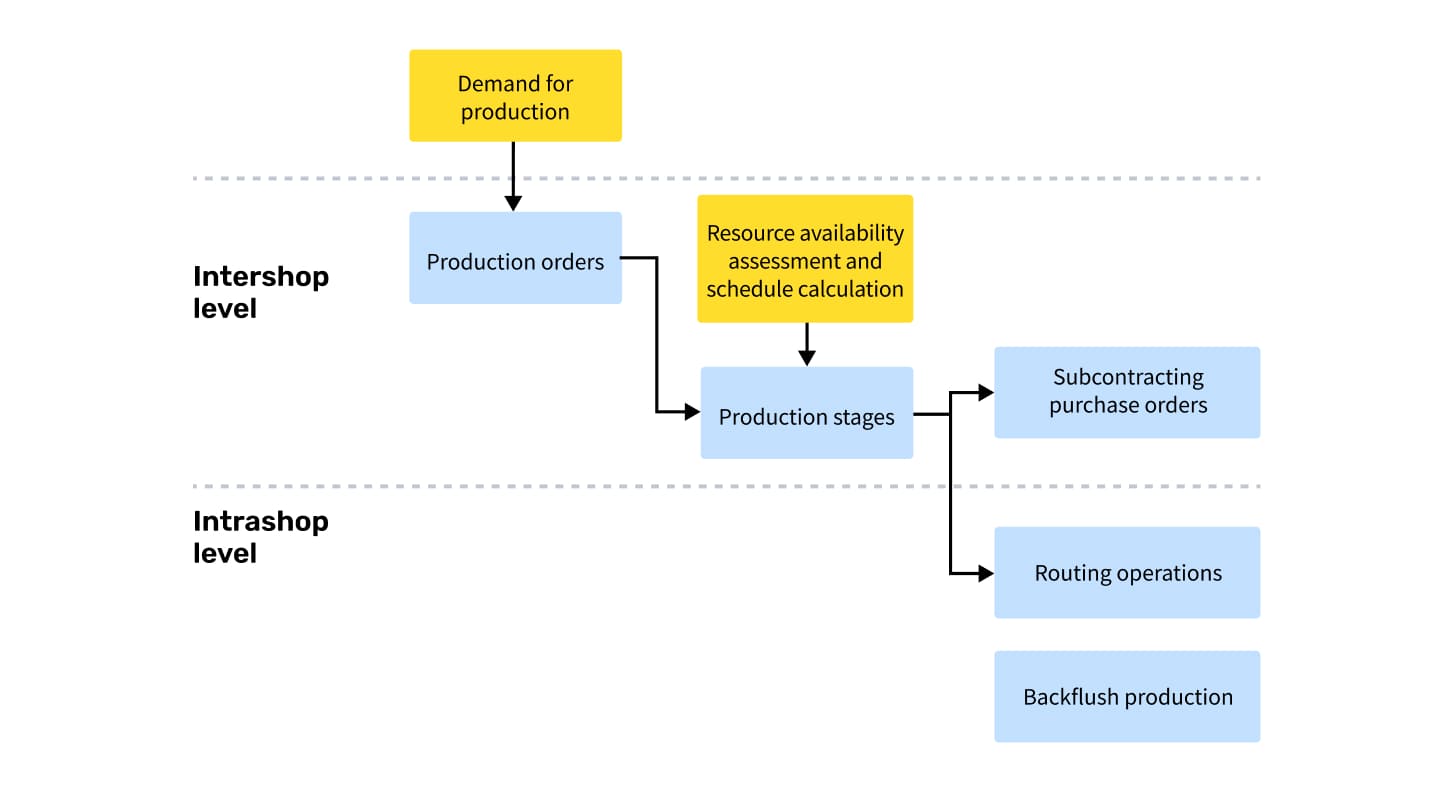

Generating demand for production

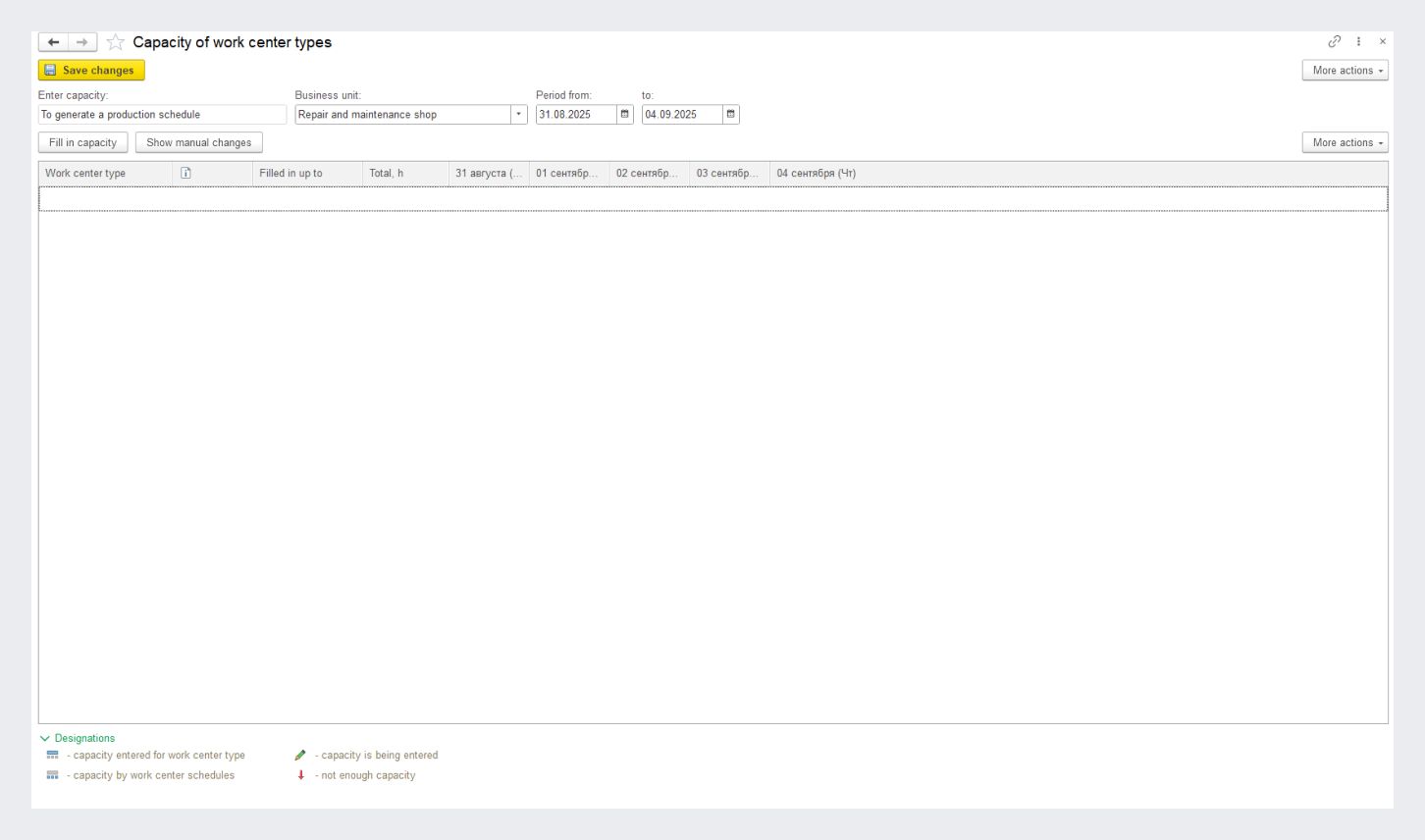

Production Scheduling

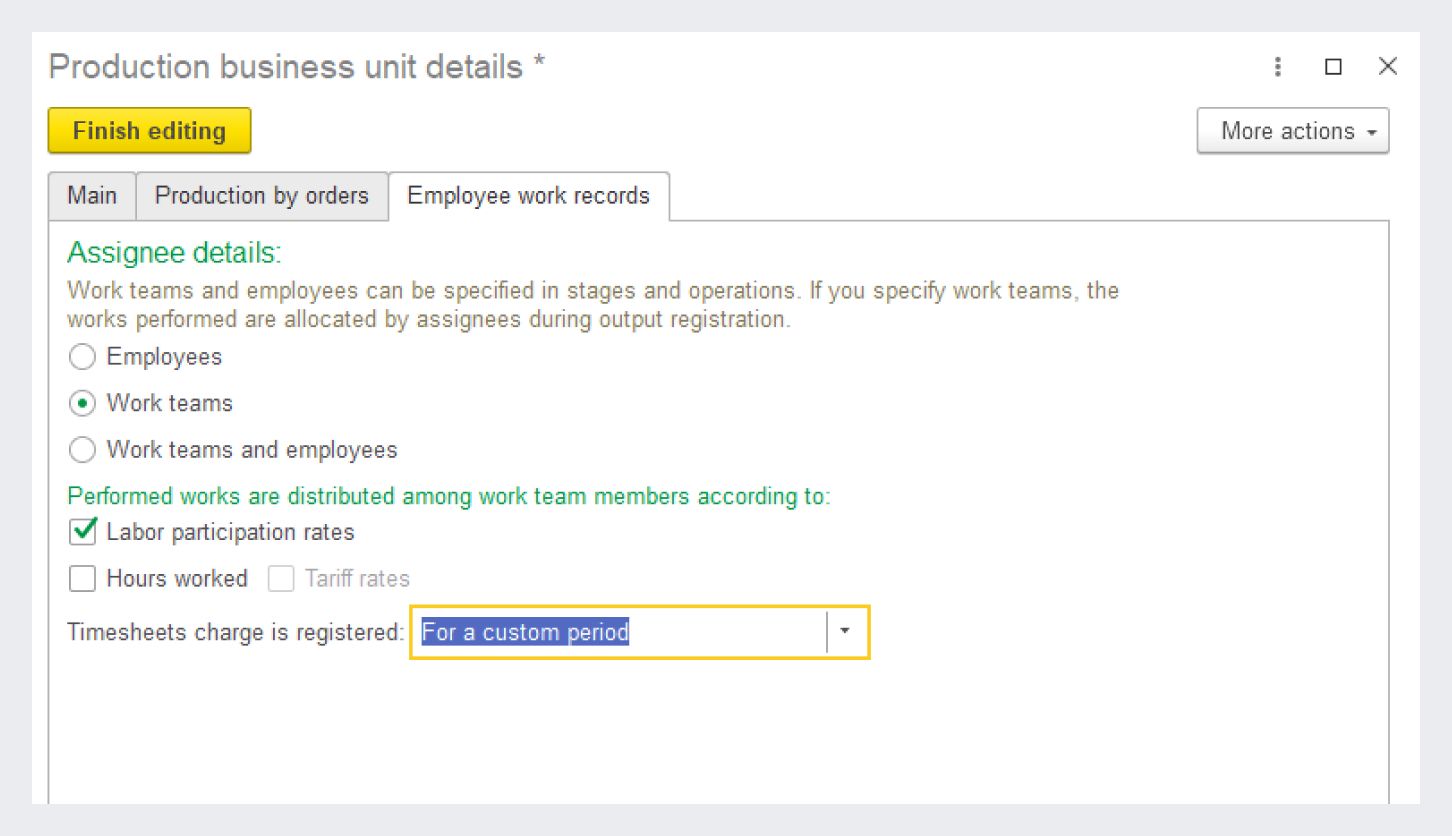

Shop Floor Management

Request Demo

Apply for a free personalized product demo and see the value of

1C:ERP yourself.