Customer

Ager MakinaPartner

iQM Technology SoftwareIndustry

Machinery Production

Country

Turkiye

Product

1C:Drive

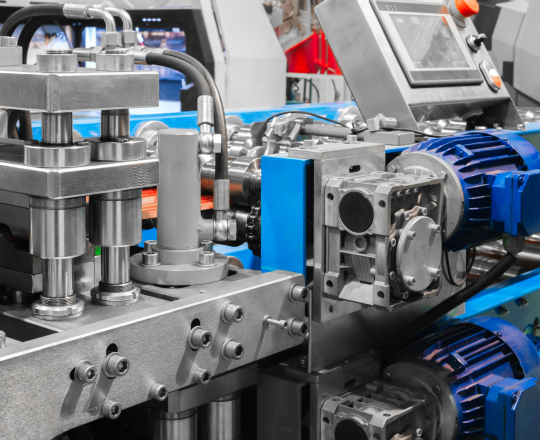

Ager Makina, also known as Ager Machining Co. Ltd., operates in the field of industrial facilities, custom machine manufacturing, hydraulic presses, steel structures, machining, and other related services. With 17 years of experience in the industry, Ager Makina excels in steel manufacturing by prioritizing dependability, customer service, and quality to provide its clients with superior results. The company's strength is further demonstrated by its large team of over 150 employees.

Challenges

1C:Drive

Flexible and comprehensive ERP solution capable of automating the majority of processes in companies of any size. The software combines multiple capabilities to execute various business operations, manage production workflows, digitize paper streams, and connect companies to their partners. 1C:Drive helps companies to boost their growth and help stay competitive in the dynamic business environment.

What was done

Process

During the implementation, the following business processes were automated:

Planning and production management

Foreign trade management

Sales management

Marketing management

Warehouse management

Quality control

Quality assurance

Finance management

Customer success

“It's not just about the remarkable numbers; it's about how 1Ci products have empowered Ager Makina to deliver superior quality with a sharper competitive edge in the steel manufacturing industry.”

Results

Related Customer Stories

Interested in 1Ci solutions?

Tell us about your project and we'll find the best 1Ci partner to help.